Letterpress Printing

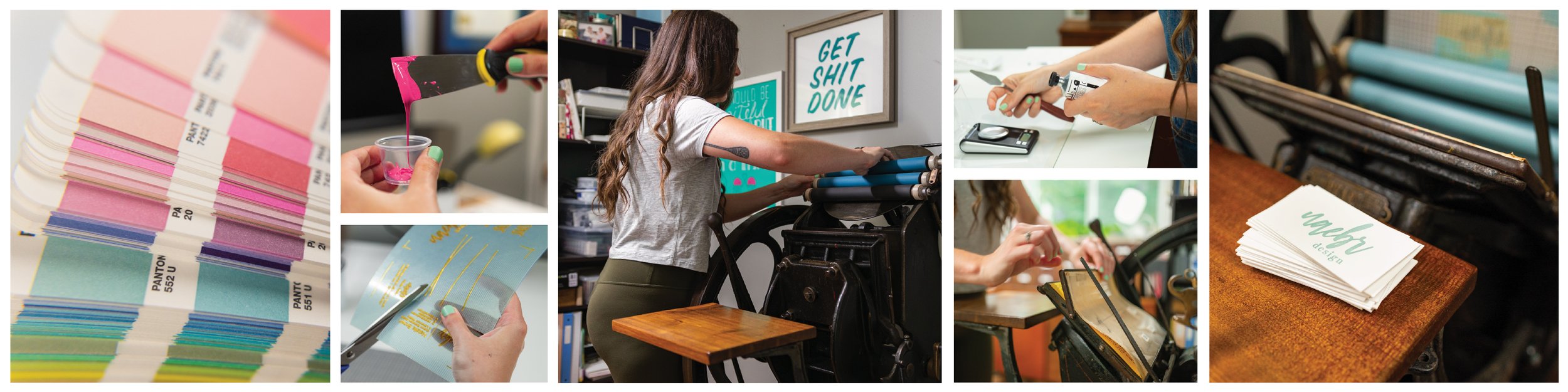

Letterpress printing is an age-old craft that continues stealing modern hearts - including my own. There is always something new to learn, new techniques to try, and ample opportunity for creativity and problem-solving. I love sharing the history and process of letterpress printing, as well as what I’m learning along the way. It is such a niche art form for those outside of the letterpress bubble, but I have yet to find someone who doesn’t find some aspect of it fascinating (you reading this means it’s true, by the way).

The Presses

‘Chuck (Mangione)’

This Golding Pearl 11 is the studio workhorse that made me a letterpress printer in 2021, and is the machine behind every Naebr card. Chuck is a Golding Pearl Improved #11 printing press and was manufactured way back in 1897 in Boston. He relies solely on foot-peddle power, and works best when printing anything smaller than 5x7 (ish) inches.

‘Freddy Prints Jr.’

Freddy was a welcomed addition to the studio in 2022. A spring chicken compared to Chuck, this Freemont Proofing Press was manufactured in the early 1920s in New York (from the best I can tell). Works exceptionally well with both type and polymer plates, and it is currently used for all of our art prints.

letterpress products + services

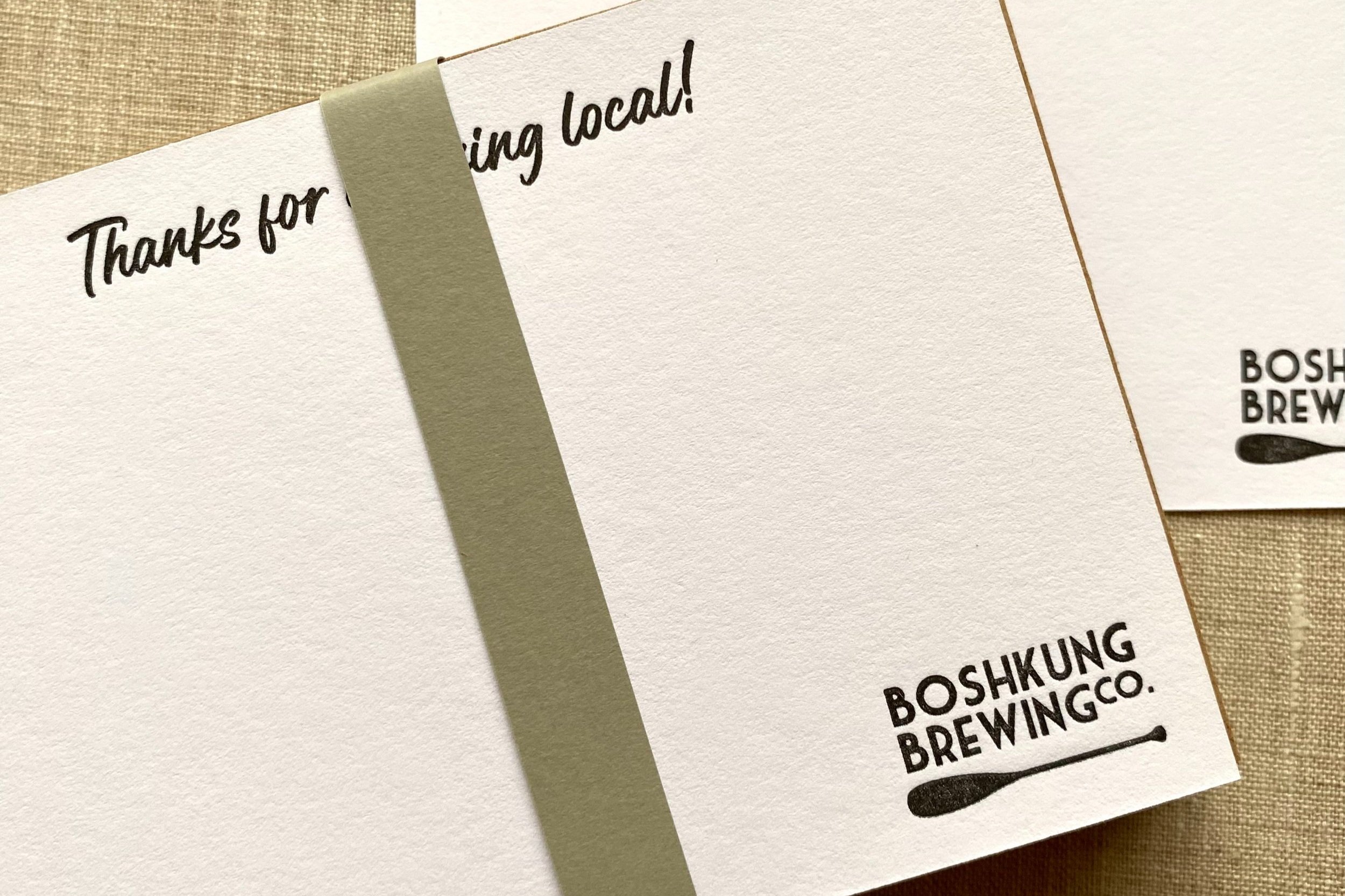

greeting cards

notecards

business cards

art prints + decor

wedding invitations

personalized stationery

business + brand stationery

letterpress printing for designers

Looking for a quote, questions about printing capabilities, or for something not listed above?

Send me your project details and I’ll let you know if it’s a good fit!

How it Works

01. inspiration + inquiry

So, you’re thinking about custom letterpress printing - I am so proud. Start by having a look around the site to get an idea of what I offer as far as products and past projects. Gather colours, logo files, and any other inspiration photos that may help with filling out your Letterpress Printing Inquiry form.

Still not quite sure where to start? Book a free consultation instead and we can chat by phone, video chat, or in person to get the ball rolling.

02. quote + contract

I’ll take a close look at all of the information you provided, get additional details if necessary, and send you a quote based on what you’re looking for. We can discuss any questions, make changes if needed, and when you’re happy we can move on to the next step. I will send you your contract with the project details, and collect a 50% retainer required before the design process can start. Then the fun part begins!

03. design + production

You’ll provide me with all of the things - wording, necessary files, logos, colour choices - and design time will begin once this is received. You will be sent your first proof, and we will work through any design changes that are required. When you have signed off on the final design I’ll send it off to have plates made, and then begin the printing stage. Once everything is ready you will be notified, the remaining balance will be collected, and then your stationery will be delivered or mailed, ready to be enjoyed!

letterpress lingo

Letterpress

A form of relief printing where individual sheets of paper are hand-fed into a press to print a desired piece of text or artwork. A form with the raised design is placed in a press, inked, and paper is pressed against it to transfer the ink onto the paper.

Ink / Colours

All of our ink is mixed by hand using the Pantone Uncoated formula guide. ‘Colours’ also refers to the number of times a piece goes through the press. If a card is printed with only black ink but on both sides, it is still considered a 2-colour project.

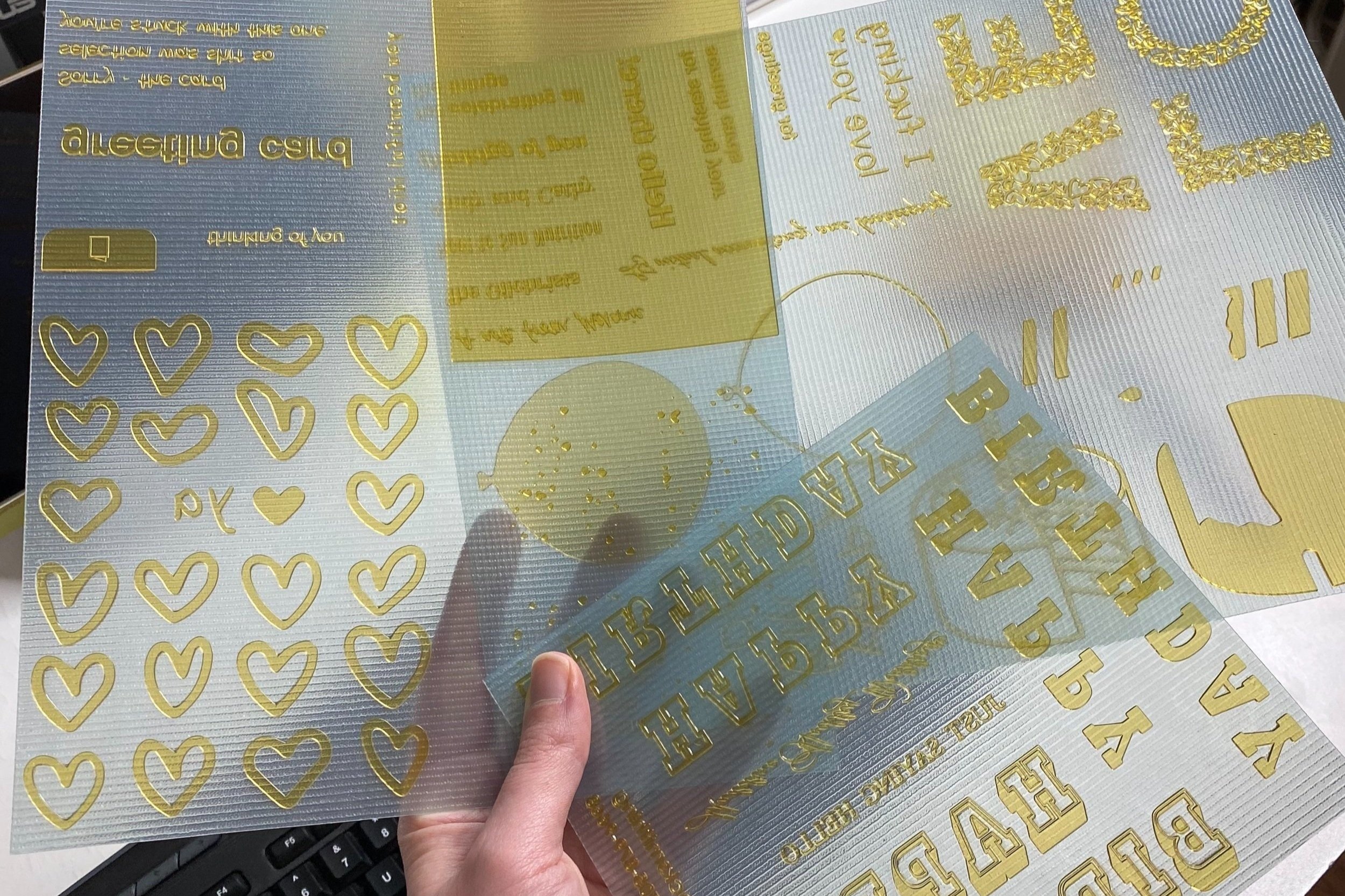

Plate

A modern alternative to type, photopolymer plates are convenient, cost-effective and offer a wide range of design options. Using UV light and a film negative, the design hardens on the plate creating a perfectly level, type high ‘stamp’ to use on the press.

Blind Impression

When a piece is run through the press with a plate that is not inked. Impression depth that can be achieved it dependant on the press, size of the printed area, and paper choice. Even though there is no ink it still counts as 1 ‘colour’ (see ink / colours)

Type

Naebr Design has a small but well-used collection of both metal and wood type. Individual letters are typeset, locked up in a form, and inked and printed similarly to plates. Custom requests with type are limited to the fonts in my current collection.

Deboss

Debossing is when an image - logo, text, etc. - is imprinted into your print piece leaving an imprint. Anything printed on my presses is a deboss, regardless of whether or not it is printed with ink, without ink, or the depth of the impression.

Setup / Makeready

Both terms are used to describe the process of making the press ready to print by oiling, inking, and making adjustments until an even impression and coverage are achieved. Each colour being printed for the project needs its own setup.

Saltiness / Ink coverage

Printing larger areas of colour are not very letterpress friendly, offer less impression and lead to a ‘salty’ or mottled ink coverage. Some people love the textured look, but it makes consistency in colour and coverage difficult to achieve.